Recently, the FTXT's IV hydrogen storage tank production line was officially completed in Baoding Industrial Park and entered the trial production stage, marking that FTXT has the large-scale production capacity of the Type IV hydrogen storage tank and has taken a surprising leap in industrialization development.

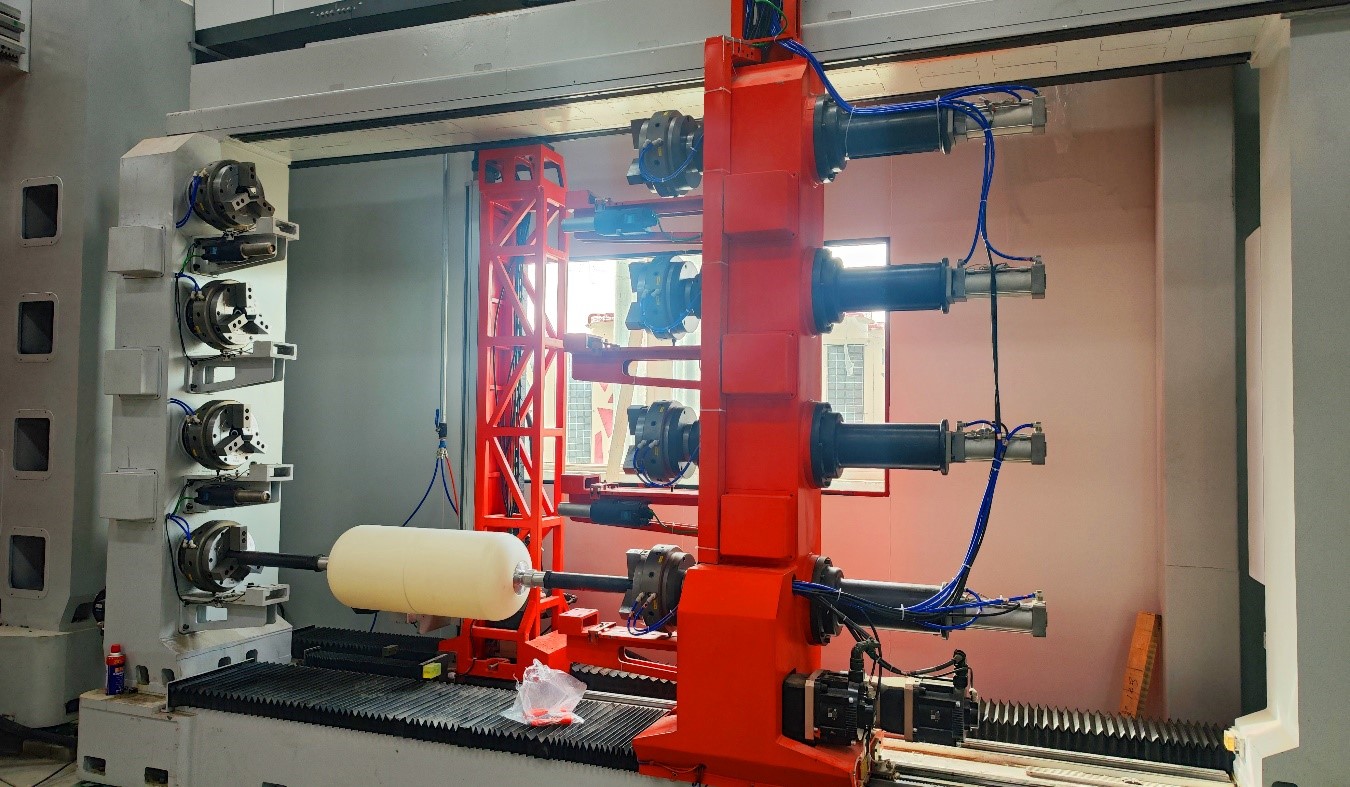

The production line workshop covers an area of more than 4,000 square meters and has introduced high-end fully automated intelligent production lines. The whole production line includes a complete production process, such as inner liner forming, surface treatment, fiber winding, curing, inspection and testing, product packaging, etc. And the physical, chemical, and mechanics laboratory can carry out the physicochemical and mechanical evaluation experiments of metal and non-metal materials, such as inner liner material, inner liner, valve seat, aluminum alloy, sealing ring, checking ring, carbon fiber, glass fiber, epoxy resin composite material. This production line facilitates FTXT to realize the closed-loop control of the whole process from design and development to quality inspection, ensuring product consistency, reliability, and safety.

After the project is put into operation, the production capacity of the hydrogen storage tank can reach 10,000 pcs/year, which is expected to be officially put into production at the end of 2023 for global market supply. By 2026, the planned production capacity will be expanded to 100,000 tanks per year.